Introduction to Vacuum Deaerator

A vacuum deaerator is a device that allows water to boil at low temperature under vacuum, removing gases such as oxygen, nitrogen, and carbon dioxide from the water. It consists of two main parts: a deaeration water tank (deaeration tower) and a vacuum unit. The deaeration water tank can be arranged at a high or low position, and the vacuum pump unit can use a steam jet pump powered by steam or a water jet pump powered by circulating water as the working medium.

In the process of water treatment, deoxygenation is a non critical step. Oxygen is the main corrosive substance in the water supply system and boiler. Oxygen in the water supply should be quickly removed, otherwise it will corrode the water supply system and components of the boiler. The corrosion product, iron oxide, will enter the boiler, deposit or adhere to the boiler tube wall and heating surface, forming insoluble and poor heat transfer iron scale. Moreover, corrosion can cause pits on the inner wall of the pipeline and increase the resistance coefficient. When pipeline corrosion is severe, pipeline accidents may even occur- According to regulations, steam boilers with an evaporation capacity of 2 tons or more per hour and hot water boilers with a water temperature of 95 ℃ or more are required to undergo deoxygenation- In recent years, many boiler feedwater treatment workers have been exploring both high and economical deoxygenation methods, and vacuum deoxygenation is one of them- According to regulations, steam boilers with an evaporation capacity of 2 tons or more per hour and hot water boilers with a water temperature of 95 ℃ or more require deaeration, and vacuum deaerator is a type of deaerator equipment

A vacuum deaerator is a device that allows water to boil at low temperature under vacuum, removing gases such as oxygen, nitrogen, and carbon dioxide from the water. It consists of two main parts: a deaeration water tank (deaeration tower) and a vacuum unit. The deaeration water tank can be arranged at a high or low position, and the vacuum pump unit can use a steam jet pump powered by steam or a water jet pump powered by circulating water as the working medium.

In the process of water treatment, deoxygenation is a non critical step. Oxygen is the main corrosive substance in the water supply system and boiler. Oxygen in the water supply should be quickly removed, otherwise it will corrode the water supply system and components of the boiler. The corrosion product, iron oxide, will enter the boiler, deposit or adhere to the boiler tube wall and heating surface, forming insoluble and poor heat transfer iron scale. Moreover, corrosion can cause pits on the inner wall of the pipeline and increase the resistance coefficient. When pipeline corrosion is severe, pipeline accidents may even occur- According to regulations, steam boilers with an evaporation capacity of 2 tons or more per hour and hot water boilers with a water temperature of 95 ℃ or more are required to undergo deoxygenation- In recent years, many boiler feedwater treatment workers have been exploring both high and economical deoxygenation methods, and vacuum deoxygenation is one of them.

Composition of vacuum deaerator

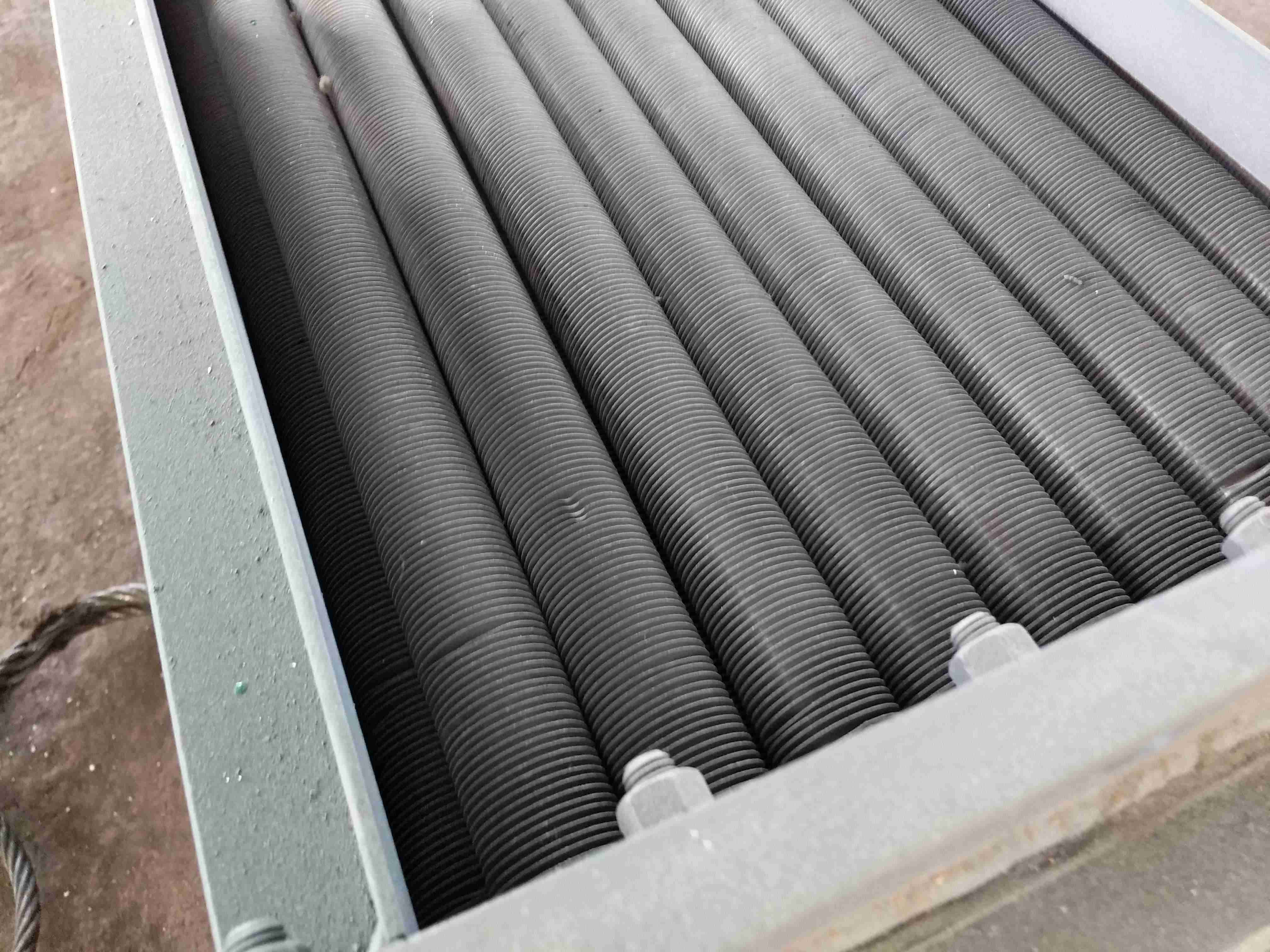

Vacuum deaerator mainly consists of deaerator (deaerator head and deaerator water tank), high pressure rotary membrane device, water jet vacuum pump unit, water intake pump unit, etc.

The deaerator is equipped with a high spin film device, which changes the natural falling film to a strong falling film, increases the viscosity of the liquid film, and causes the liquid film to rotate strongly along the pipe wall, enhancing dispersion and mass transfer functions; Change the opposed bubble boiling to a suspended bubble boiling. When the layer water vapor velocity is high, it will splash and maintain the vapor (gas) channel; Simplify the three heat and mass transfer methods into a body and complete them within a unit of components. Due to its high efficiency and certain special functions, it has surpassed the technical capabilities of existing deaerators.

When the deaerator is running, the deaerator water tank is in a negative pressure state. When installed at a high position, the distance between the outlet of the water tank and the boiler feedwater pump should be relatively large, not less than 10 meters; When installing at a low position, the outlet of the water tank is connected to the water intake pump unit, so that the negative pressure water is pressurized and enters the boiler feedwater pump.

The water jet vacuum pump unit is equipped with a long throat water jet air pump, which has a compact design structure and low power consumption. And it has a high suction rate, with a suction capacity of - times that of - under the same conditions. Non low noise level, no vibration, simple installation arrangement.

The function of the water intake pump unit is to boost the negative pressure water through the water intake pump and connect it to the boiler feedwater pump during the low installation of the deaerator.

The vacuum deaerator can operate continuously throughout the year, requiring a backwash process, which is energy-saving and water saving

The composition and structure of vacuum deaerator The working principle of vacuum deaerator is based on the application of Henry's law and Dalton's law. According to Henry's law, in a closed container, if any gas exists simultaneously on the water surface, the solubility of the gas is directly proportional to its own partial pressure, and the solubility of the gas is only related to its own partial pressure. At a constant pressure, as the water temperature increases, the partial pressure of water vapor increases, while the partial pressure of air and oxygen decreases. At 100 ℃, the partial pressure of oxygen decreases to -, and the dissolved oxygen in water also decreases to -. When the pressure on the water surface is lower than atmospheric pressure, the solubility of oxygen can also reach - at lower water temperatures. In this way, oxygen molecules in the space above the water surface are discharged or transformed into other gases, resulting in a partial pressure of oxygen of -, and water oxygen continuously escapes, achieving the goal of deoxygenation. This deoxygenation method is generally carried out at temperatures ranging from 30 ℃ to 60 ℃. Vacuum deoxygenation can be used to achieve satisfactory deoxygenation results for both thermal boilers and steam boilers with large load fluctuations and ineffective thermal deoxygenation under low temperature conditions on the water surface (at 60 ℃ or - temperature). Compared to thermal deoxygenation technology, its heating conditions are required to be very low, the self consumption of steam in the boiler room is reduced, and the vacuum deoxygenator can be arranged at a low position. The requirements for operating and managing key equipment such as jet pumps and booster pumps are higher than those for thermal deoxygenation. The low-level layout also requires a certain height difference and high requirements for the operation and management of key equipment such as jet pumps and booster pumps.

Model Specification Parameters Model Representation Method ZCY-50T/H

|| ------ Treatment water volume 50T/H

|----------Model parameters of vacuum deaerator

| 型 號 參 數(shù) | ZCY-4 | ZCY-6 | ZCY-10 | ZCY-20 | ZCY-35 | ZCY-50 | ZCY-100 |

| 額定出力T/H | 4 | 6 | 10 | 20 | 35 | 50 | 100 |

| 工作真空度Kpa | 18.6~21.3 | 18.6~21.3 | 18.6~21.3 | 5.3~80 | 5.3~80 | 5.3~80 | 5.3~80 |

| 飽和水溫度℃ | 62.5 | 62.5~57.5 | 62.5~57.5 | 42.5~37.5 | 42.5~37.5 | 42.5~37.5 | 42.5~37.5 |

| 進水壓力MPa | ~0.2 | ~0.2 | ~0.2 | ~0.2 | ~0.2 | ~0.2 | ~0.2 |

| 出水含氧量ug/l | 0.05~0.1 | 0.05~0.1 | 0.05~0.1 | 0.05~0.1 | 0.05~0.1 | 0.05~0.1 | 0.05~0.1 |

| 水箱直徑mm | Φ900 | Φ1200 | Φ1400 | Φ1600 | Φ1800 | Φ2000 | Φ2800 |

| 除氧頭直徑mm | Φ500 | Φ600 | Φ600 | Φ800 | Φ900 | Φ1000 | Φ1400 |

| 設備-量kg | ~1150 | ~1320 | ~1800 | ~2650 | ~3900 | ~5450 | ~8760 |